Just after the Second World War, DRT devised a way to extract beta-sitosterol from maritime pine. Based on this experience, the company has developed an innovative process that enables it to extract OPC from grape seeds: CRYSTAL pure technology.

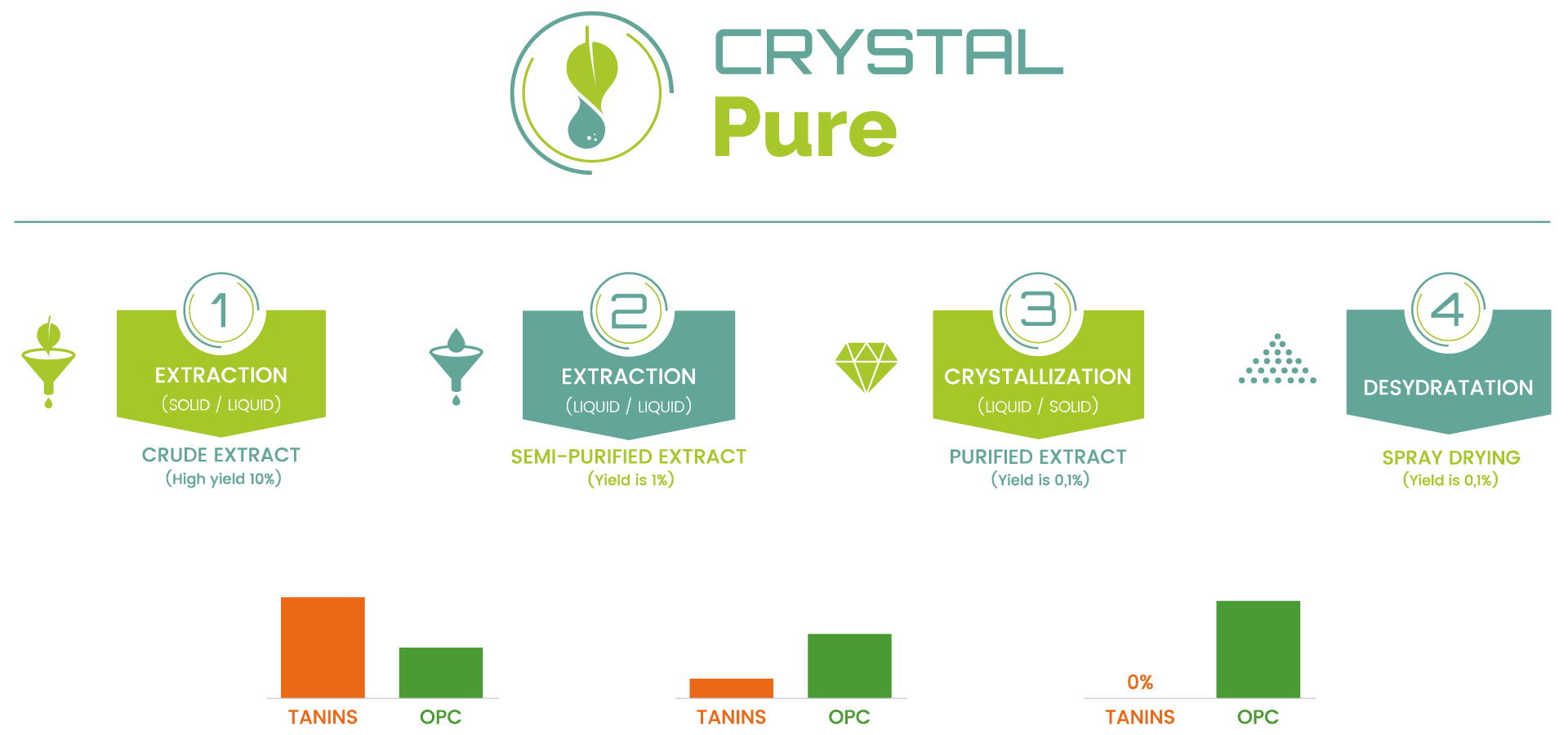

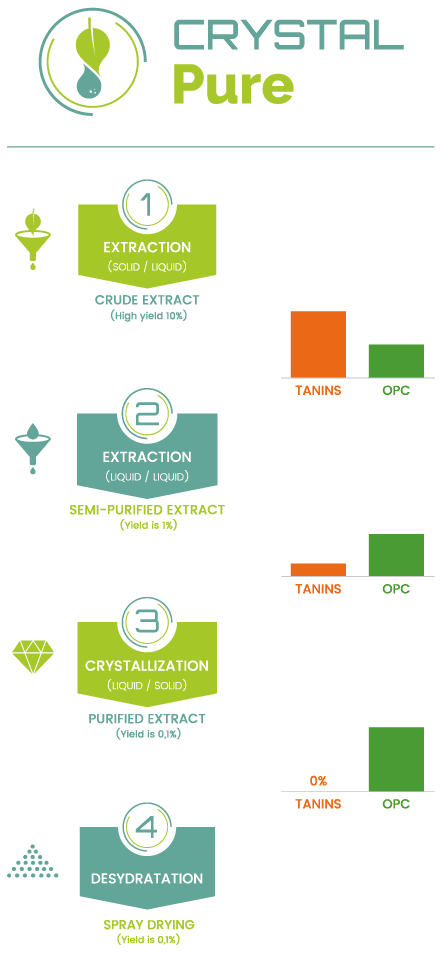

It is divided into four stages, perfectly respectful of the environment, since they use only hot water and a food grade solvent. At each stage, high molecular weight OPCs (tannins) are gradually eliminated, while low molecular weight and bio-available/bio-active OPCs (dimers, trimers, tetramers and pentamers) are concentrated.

A tradition: high expectations

LOCAL AND TRACEABLE PRODUCTION

The raw material from which DRT extracts its OPCs is a by-product of a wine-producing sector with long-standing traditions. The owners, often grouped in cooperatives, ensure regular renewal, so as not to generate depletion of the resource.

The grape seeds treated by DRT are all from the Champagne and Bordeaux vineyards. It is at the gates of the latter territory, in Vielle-Saint-Girons that DRT has located its manufacturing unit.

THE « MADE IN FRANCE »

Health, elegance, gastronomy, body care and quality of life “à la française” is popular throughout the world. It constitutes a true brand image, based on a very real tradition of epicureanism and rigour.

DRT’s OPC production unit meets the quality levels required by ISO 22000, ISO 9001, HACCP and cGMP certifications. Vitaflavan® is in conformity with the United States Pharmacopeia (USP).

Vitaflavan® is in conformity with the United States Pharmacopeia (USP).

Vitaflavan® is compliant with California proposition 65.